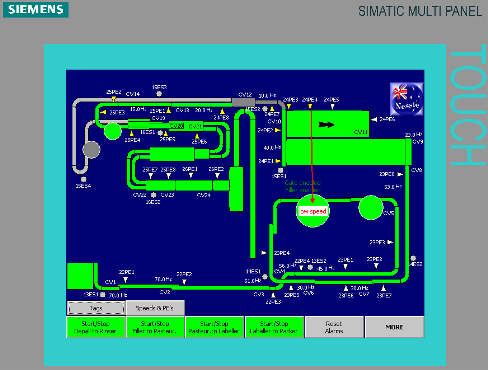

Overview and Description for a new Conveyor Control / Bottling Line Control

The target for the Conveyor Control Project was the automatic Line Control and automatically adjustable speeds to increase production efficiency.

We've choosen the Siemens Simatic PLC S7-315 CPU, the Siemens HMI MP277 Touch Multi Panel and 24 Siemens Micromaster Variable Speed Drives (VSD) with Profibus Modules.

External Machines are hooked up to the Siemens Simatic PLC S7-315 CPU for interlocks. Status and Alarm Messages from all Conveyors, Drives and Machines are displayed on the Siemens HMI MP277 Touch Multi Panel.

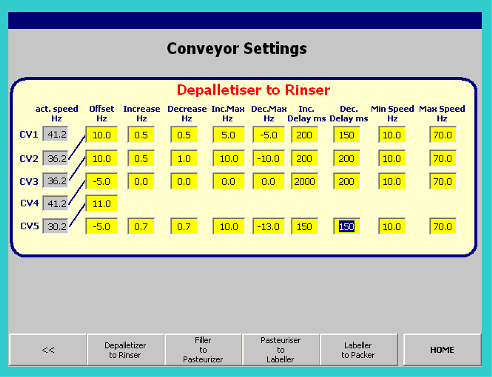

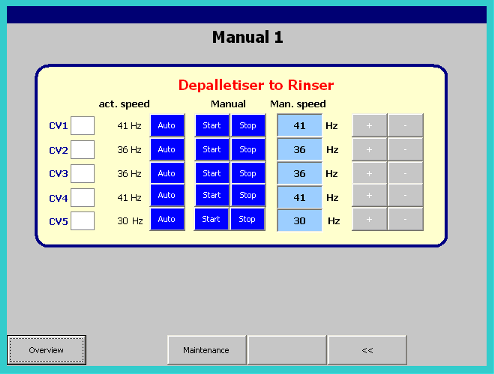

Conveyor Speeds are fully automatically adjusted to follow the required Filler Speed, but also to fill up the Line in case of a lack of Product.

The Maintenance Department is able to adjust nearly each Parameter on the Siemens HMI MP277 Touch Multi Panel without using a Laptop or Field PG, no PLC Programmer is required.

The PLC Program contains our own Standard Blocks to minimize the Programming Time and for easier troubleshooting.

Nessie Services PLC Programmers have successfully used Standard Blocks overseas many years and they are appreciated by our Customers.

We can choose from a wide range of our own Standard Modules for PLC's and HMI's, please ask us for details.