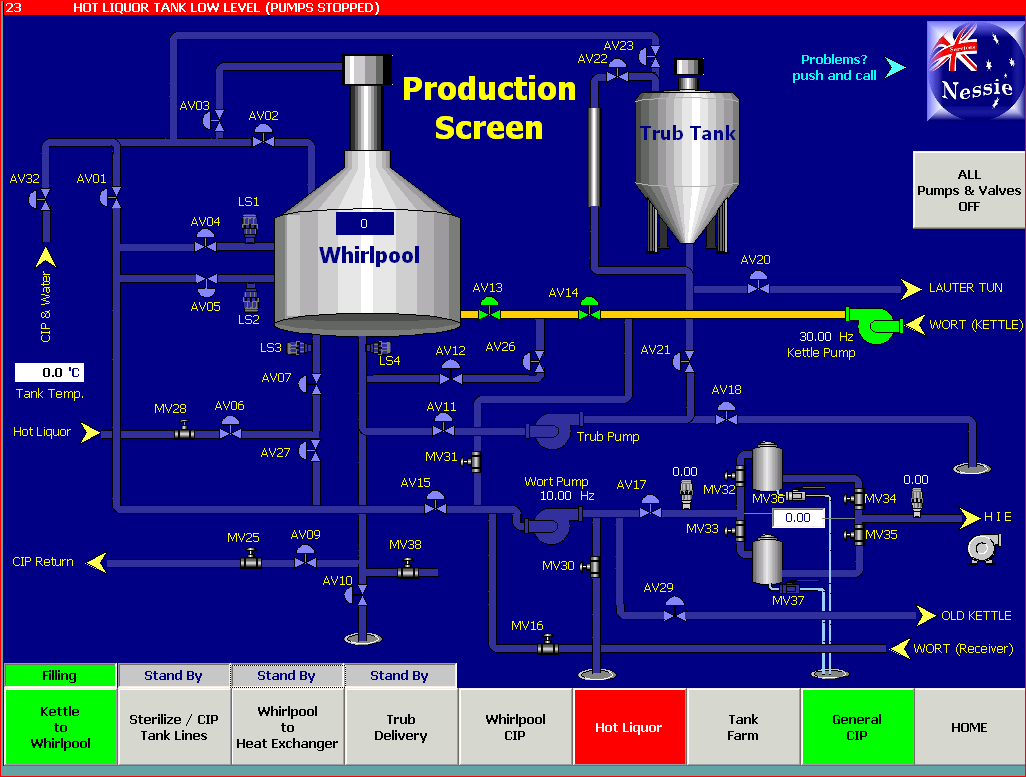

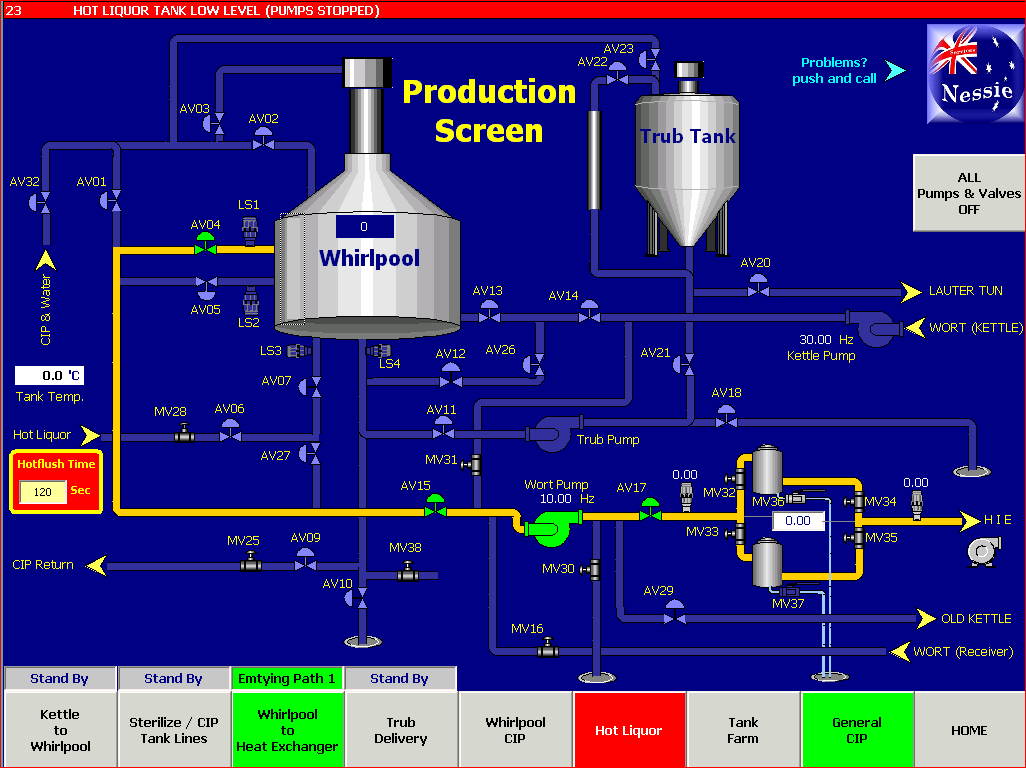

Nessie Services was asked for a Brewery Automation Upgrade for a new Whirlpool.

Our Engineers developed, designed and commissioned the PLC and HMI Hardware, and designed the HMI Screens operator optimised.

The Sequencers have been written in S7 Graph to control the different functions.

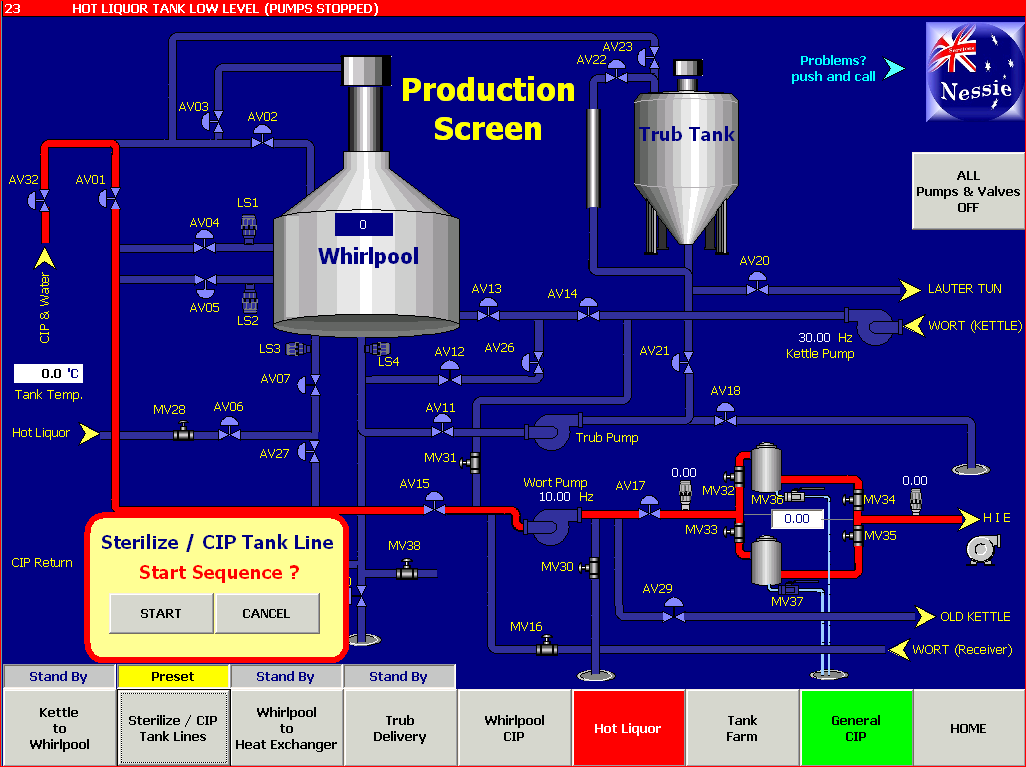

When a Sequence is selected, it won't start up straight away, it will highlight the Path and the operator can double check that the right function is choosen. The upcoming PopUp with the Start and Cancel buttons needs to be used to confirm the Sequencer start.

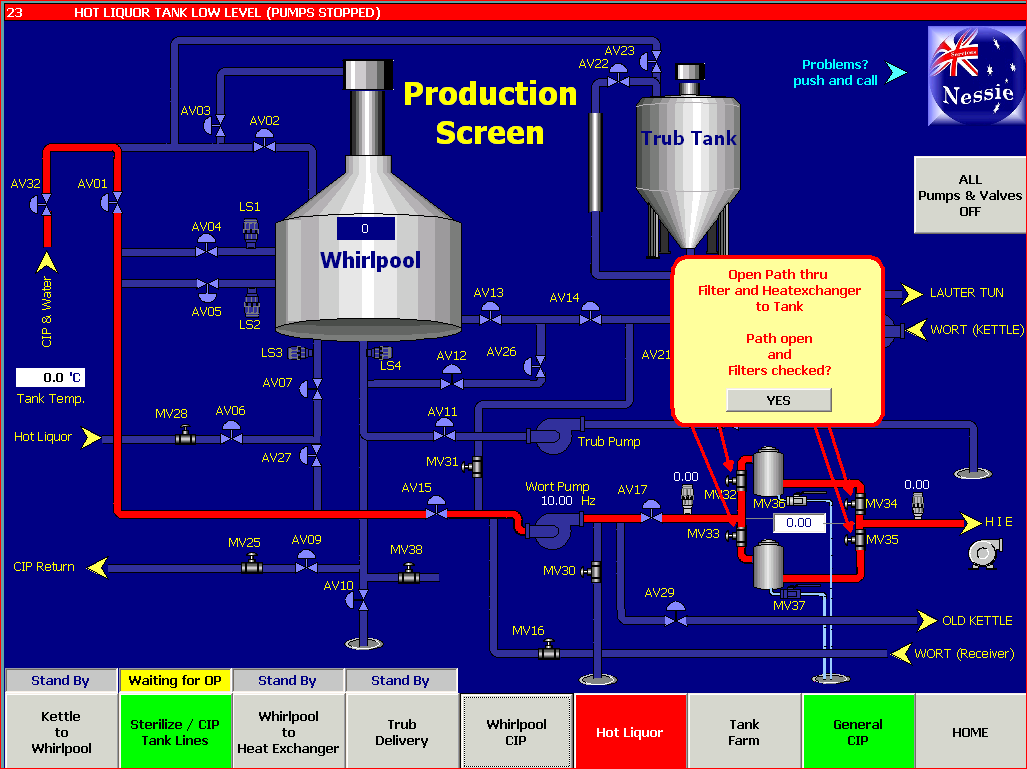

After the Sequence has started, a PopUp will appear when some manual actions needs to be taken, i.e. are the manual valves open for this path? If confirmed, Sequencer will carry on.

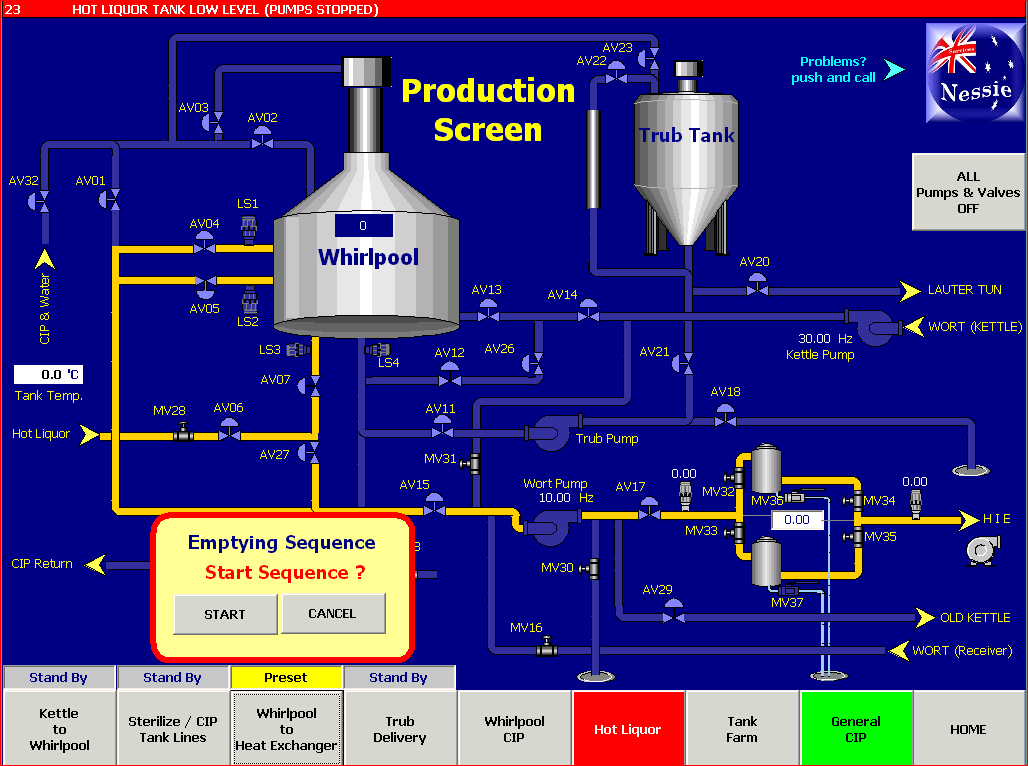

The next pic shows the preset of the Emptying Sequence with all paths activated.

The first step will empty the Whirlpool until the empty pipe switch is not active anymore.

The switch over to the next pipe is double checked with the Radar Level Probe to ensure the switch over even when the empty pipe switch isn't working anymore.

Unnecessary to mention that the setpoints are adjustable from the Touch Panel as well as the Logic is working in a way to avoid waterhammer during switch over.

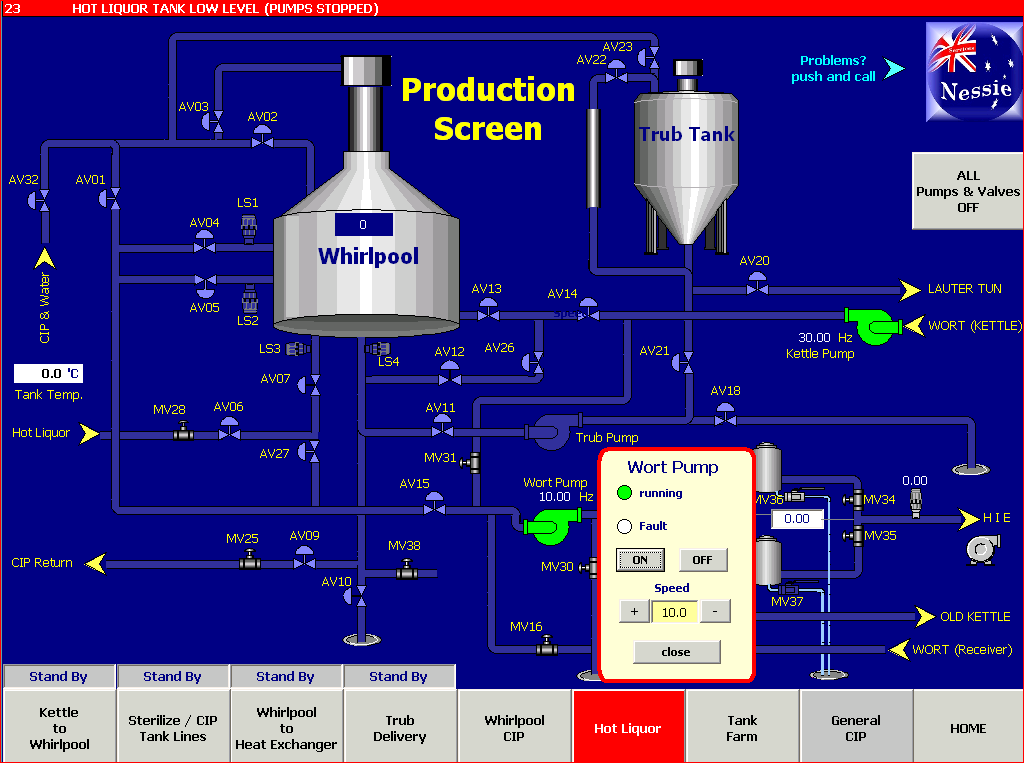

Of course each valve and pump can be operated manually (PopUp appears when touching the icon on the screen). If the pump is on a VSD the speed can be set as well.

Components:

PLC:

Siemens Simatic S7 317 CPU with several digital and analog In- and Output cards

HMI:

Siemens Simatic Multipanel MP277 10" Touch

Buerkert Solenoid Bank connected via profibus to PLC

Several Variable Speed Drives controlled via digital and analog signals

Software:

Siemens Simatic Step7 Professional

WinCC Flexible 2008 (Advanced)